Blog | Life Sciences

8th January, 2025

Sarath Kumar Vaithinathasamy is a highly skilled business analyst with over 12 years of IT experience, including three years in the life sciences domain. He has successfully contributed to digital transformation projects in eCOA platforms, clinical trials, and regulatory compliance. Sarath excels in Agile methodologies, stakeholder management, and aligning technology with business goals. His expertise in eClinical systems and patient-centric innovations ensures operational excellence, driving impactful solutions in global healthcare and life sciences environments.

AI-powered Electronic Batch Record (EBR) systems redefine batch processing for pharma enterprises, helping them cut costs and respond to regulatory imperatives with rigor.

Every efficient pharmaceutical manufacturing process relies on robust inventory management and EBR to streamline production.

Inventory management is responsible for tracking stock levels and managing production requests, while EBR focuses on the finer details like automating and overseeing the step-by-step manufacturing workflow. Even though inventory management is essential for material tracking and resource planning, it doesn’t provide the granular level of control and monitoring required for end-to-end manufacturing. EBR solves this problem to an extent in the manufacturing process:

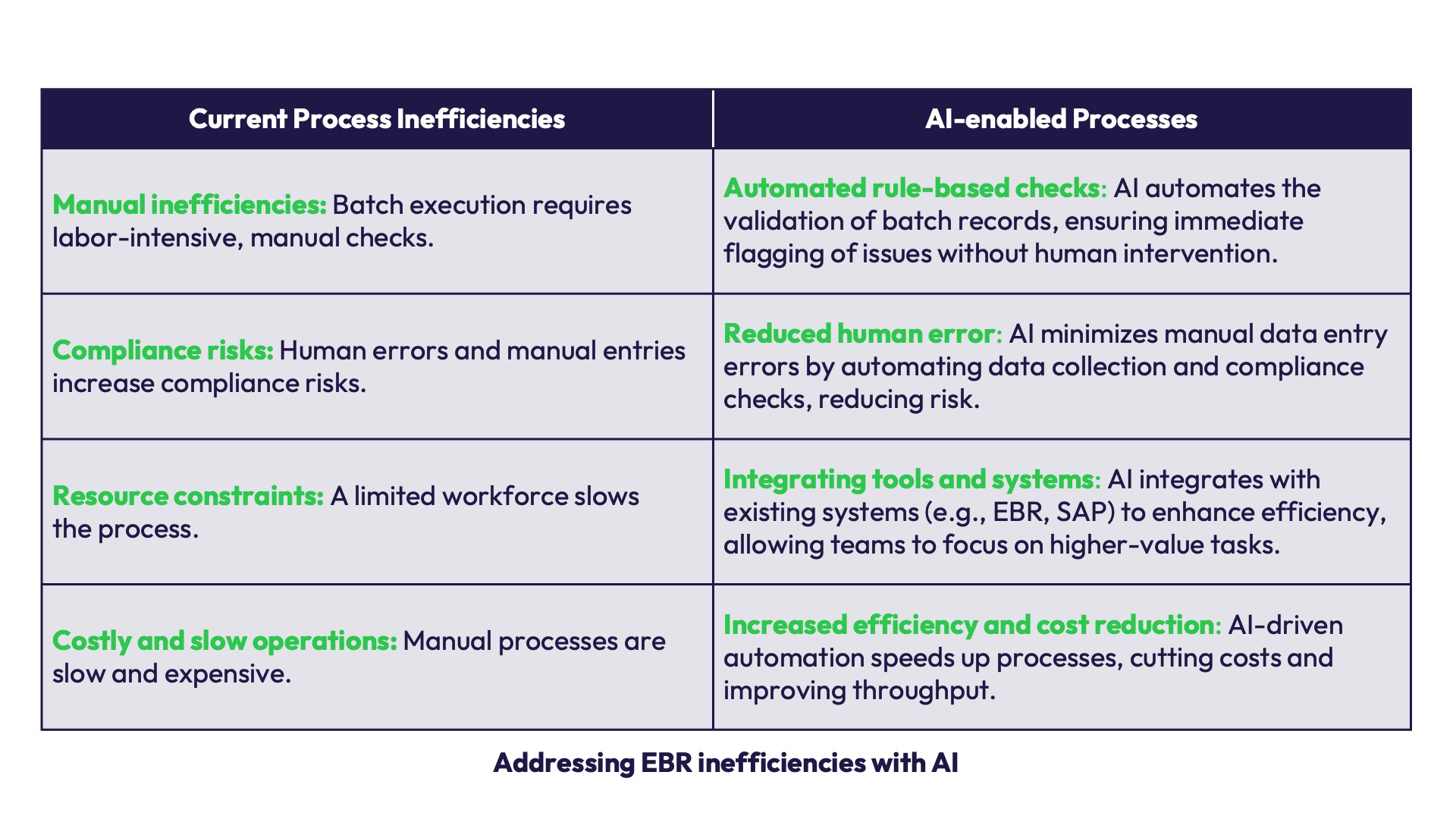

It is important to note that, in pharmaceutical manufacturing, compliance, efficiency, and accuracy in batch execution are crucial to ensuring product quality and safety. Automated, traditional EBR systems still face rigid complexities and significant resource requirements. AI’s integration into the EBR process drives intelligent automation and helps pharma companies enhance operations and simplify regulatory compliance. AI automates critical steps and strengthens data integrity and predictive insights to streamline batch releases.

Let’s examine how a few leading companies have integrated AI into their EBR systems.

Pfizer uses AI in its EBR systems to streamline data entry, automate compliance checks, and predict equipment maintenance needs. During the production of the COVID-19 vaccine, Pfizer implemented AI tools to process vast amounts of data quickly and ensure compliance with strict regulatory standards across multiple geographies. The integration of AI helped the company release batches faster while maintaining quality.

GSK uses AI to monitor batch quality in real time. They implemented AI algorithms to analyze deviations in the production of their biologics, reducing batch release times and increasing overall productivity. AI-driven automation has helped GSK ensure accurate process documentation while mitigating human error.

Novartis has integrated AI into its production lines to optimize batch processing times. For example, in the production of gene therapies, Novartis leverages AI to monitor real-time data from EBR systems, identifying bottlenecks before they impact the overall batch release. This predictive capability has allowed the company to reduce downtime and improve batch consistency significantly.

Here are seven ways AI transforms batch processing in the pharma industry.

EBR systems are intricate, requiring operators to navigate complex workflows and undergo extensive training. AI mitigates this by providing interactive, personalized training modules that guide users in real time. Swiss healthcare company Roche employs AI-powered virtual assistants to help operators through complex manufacturing tasks, reducing training time and enhancing accuracy.

Traditional EBR systems can be rigid, making it challenging to adapt to process changes. Generative AI introduces adaptive workflows that adjust dynamically based on real-time inputs and historical data. AstraZeneca, a multi-national biopharma business has successfully implemented AI-driven workflow management, enabling their production lines to adapt to changing requirements and enhancing operational flexibility.

The vast amounts of data EBR systems generate can overwhelm manual analysis efforts. AI tackles this by analyzing real-time data in real time, identifying patterns, and predicting bottlenecks. French pharma company Sanofi uses GenAI to process production data instantaneously, flagging potential deviations before they escalate and streamlining decision-making.

Setting up and maintaining EBR systems can be expensive. AI mitigates these costs by predicting system failures and automating maintenance tasks, reducing downtime and operational expenses. At Merck, a German healthcare company, AI-driven maintenance predictions have helped avoid costly breakdowns, ensuring seamless production processes.

Integrating EBR systems with other platforms like ERP or LIMS can be a significant challenge. AI improves interoperability by automating data mapping and translation, breaking down data silos. US conglomerate Johnson & Johnson uses AI to streamline data flow between ERP and LIMS systems, improving overall efficiency and data integrity.

Staying compliant with evolving regulations requires constant updates to EBR systems. Generative AI automates this process by scanning and integrating regulatory changes in real time. Eli Lilly and Company leverages AI to update their systems in response to new FDA regulations, ensuring compliance without manual intervention.

Manual data logging is prone to errors and compliance risks. AI, combined with IoT devices, automates data capture, providing accurate real-time insights. Bayer, Germany’s pharma and biotech provider, employs IoT and AI to automate data collection across their manufacturing processes, ensuring visibility and reducing compliance risks.

The advantages of AI-driven pharma batch execution:

AI-powered EBR systems offer transformative potential by streamlining workflows, automating data analysis, and strengthening regulatory compliance. These advanced systems address the complexities and inefficiencies of traditional EBR processes, significantly reducing costs and enhancing operational efficiency. AI-driven EBR solutions empower pharmaceutical companies to deliver safer, high-quality products to market with superior speed and confidence by enabling faster and more reliable batch release decisions while maintaining strict adherence to regulatory standards.